Case analysis of 11 common battery management system faults

Back

Back

2023/03/23 11:07:52

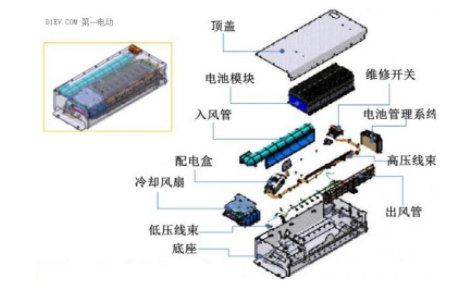

Battery management system, commonly known as battery nanny or battery housekeeper, is an important link between on-board power lithium battery and electric vehicle. Its important functions include: real-time monitoring of battery physical parameters; Battery state estimation; Online diagnosis and early warning; Charge, discharge and precharge control; Balance management and thermal management.

The battery management system is not only closely related to the battery, but also has various connections with the vehicle system. Among all the faults, compared with other systems, the fault of the battery management system is relatively high and difficult to deal with.

This paper summarizes some common methods to deal with battery management system failures and case analysis of common battery management system failures, for the vehicle, battery, management system manufacturers related personnel reference.

Case analysis of common faults

1. The whole system does not work after the system is powered

Possible causes: The power supply is abnormal, the wiring harness is short-circuited or disconnected, or the DCDC has no voltage output.

Troubleshooting: Check whether the external power supply to the management system is normal and reaches the minimum working voltage required by the management system. Check whether the power supply to the management system is insufficient due to the limited current setting of the external power supply.

The external power supply can be adjusted to meet the requirements of the management system; Check whether the wiring harness of the management system has short circuit or open circuit, modify the wiring harness to make it work normally; If the external power supply and wiring harness are normal, check whether the DCDC that supplies power to the whole system in the management system has voltage output. If an exception occurs, replace the faulty DCDC module.

2. BMS cannot communicate with ECUs

Possible cause: The BMU is not working or the CAN signal cable is disconnected

Troubleshooting: Check whether the 12V/24V power supply to the BMU is normal. Check whether the pin of the CAN signal transmission line is removed or the plug is not inserted. Monitor CAN port data to see whether BMS or ECU packets can be received.

3. Unstable communication between BMS and ECUs

Possible cause: The external CAN bus does not match properly or the bus branches are too long

Troubleshooting: check whether the bus matching resistance is correct; Whether the matching position is correct and the branch is too long.

4. BMS internal communication is unstable

Possible causes: The cable plug is loose, the CAN cable routing is irregular, or the BSU address is repeated.

Troubleshooting: check whether the wiring is loose; Detect whether the bus matching resistance is correct, whether the matching position is correct, whether the branch is too long; Check whether the BSU address is the same.

5, insulation detection alarm

Possible cause: Battery or driver leakage or insulation module detection cables are incorrectly connected.

Troubleshooting: Use the BDU display module to check the insulation detection data and check whether the battery bus voltage and negative bus voltage to the ground are normal. Insulation resistance of bus and driver to ground is measured by insulation dial.

6. The main relay does not draw after power-on

Possible causes: The load detection line is not connected, the precharged relay is open, and the precharged resistor is open.

Troubleshooting: Use the BDU display module to check the bus voltage data, check the battery bus voltage, load bus voltage is normal; Check whether the load bus voltage rises during the precharging process.

7. The data of the acquisition module is 0

Possible cause: The collection cable of the collection module is disconnected or the collection module is damaged.

Troubleshooting: Remove and reinsert the cable to the module, and check whether the battery voltage is normal at the acquisition cable connector and whether the resistance is normal at the temperature sensor cable connector.

8. The battery current data is incorrect

Possible causes: The plug of the Hall signal cable is loose, the Hall sensor is damaged, or the collection module is damaged.

Troubleshooting: reinsert the signal cable of the current Hall sensor. Check whether the Hall sensor power supply and signal output are normal; Replace the collection module.

9. The battery temperature difference is too large

Possible cause: The plug of the heat dissipation fan is loose and the heat dissipation fan is faulty.

Troubleshooting: reinsert the fan plug cable. Power on the fan separately and check whether the fan works properly.

10. The battery temperature is too high or too low

Possible causes: The plug of the heat dissipation fan is loose, the heat dissipation fan is faulty, or the temperature probe is damaged.

Troubleshooting: reinsert the fan plug cable. Power on the fan separately and check whether the fan works properly. Check whether the actual battery temperature is too high or too low. Measure the internal resistance of the temperature probe.

11. The SOC is abnormal

Symptom: SOC varies greatly during system operation, or jumps repeatedly between several values; During the charging and discharging process of the system, SOC has a large deviation. SOC always displays a fixed value.

Possible cause: current is not calibrated; Current sensor type and host program does not match; The battery is not deeply charged and discharged for a long time; Data acquisition module acquisition jump, resulting in SOC automatic calibration;

Two conditions for SOC calibration: 1) to achieve overcharge protection; 2) The average voltage reaches above xxV. Customer battery consistency is poor, overcharge, the second condition cannot be achieved. The remaining capacity and total capacity of the battery are displayed. The current sensor is not properly connected.

Troubleshooting: Calibrate the current in the touch screen configuration page; Change the host program or replace the current sensor; A deep charge and discharge of the battery; Replace the data acquisition module, manually calibrate the SOC of the system, and recommend customers to conduct in-depth charge and discharge once a week; Modify the host program, according to the actual situation of the customer to adjust the average voltage to xxV above the condition of xxV.

Previous

Previous